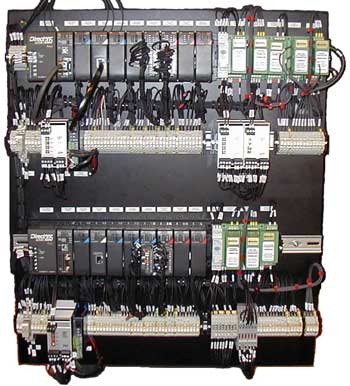

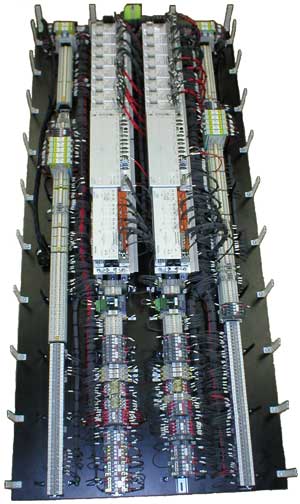

Custom Railway PLC Controls

From Northwest Rail Electric

Phone: (503) 231-4808, Fax: (503) 230-0572, E-mailSee where our equipment is located on a typical passenger car

See where our equipment is located on a typical passenger car

Here is a list of some of the various features that have been incorporated into Northwest Rail Electric PLC systems over the years:

Here is a list of some of the various features that have been incorporated into Northwest Rail Electric PLC systems over the years: